The Working Principle and Composition of Infrared Sensor

The Working Principle and

Composition of Infrared Sensor

1. The working principle of infrared sensor

After the infrared radiation of the target and the

background passes through the objective lens, it is imaged on the focal plane

of the detection component. The infrared detection component converts infrared

radiation into electrical signals, and preprocessing circuit through the

infrared signal. After the infrared signal is subjected to Correlated Double

Sample (CDS), electronic filtering, and A/D conversion, NUC, defect elimination

and synthesis sorting are performed. Then, the parallel digital signal is sent

to the potential target processing unit through a certain distance transmission

line for further processing.

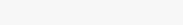

2. The components of infrared sensor

The infrared sensor is composed of objective lens

(infrared optical system), infrared detector module, infrared signal

preprocessing circuit, secondary stabilization device and control and

communication circuit. It is shown in FIG. 5.31.

2.1 Objective lens

The objective lens of the infrared sensor has high

requirements on imaging quality and optical efficiency, and the classical

optical design cannot guarantee the optical efficiency of the objective lens.

Hence, the objective lens should be designed as an aspherical transmission

optical system. The design is made of a variety of materials to correct the

chromatic aberration in the working band.

2.2 Infrared detection

components

An infrared detection component is consist

of the following parts:

(1)ID TL005 288×4 LWIR IDDCA component.

(2)Detector clock pulse generator circuit: generates the pulse signal needed to

ensure the normal operation of the detector.

(3)Detector bias circuit: generate the bias voltage required by the normal

operation of the detector.

(4)Pulse enable generator circuit, the detector CCD readout circuit pulse

enable signal generated by the Angle measurement system, pulse enable arrival,

clock pulse generator circuit is to generate the CCD required pulse signal.

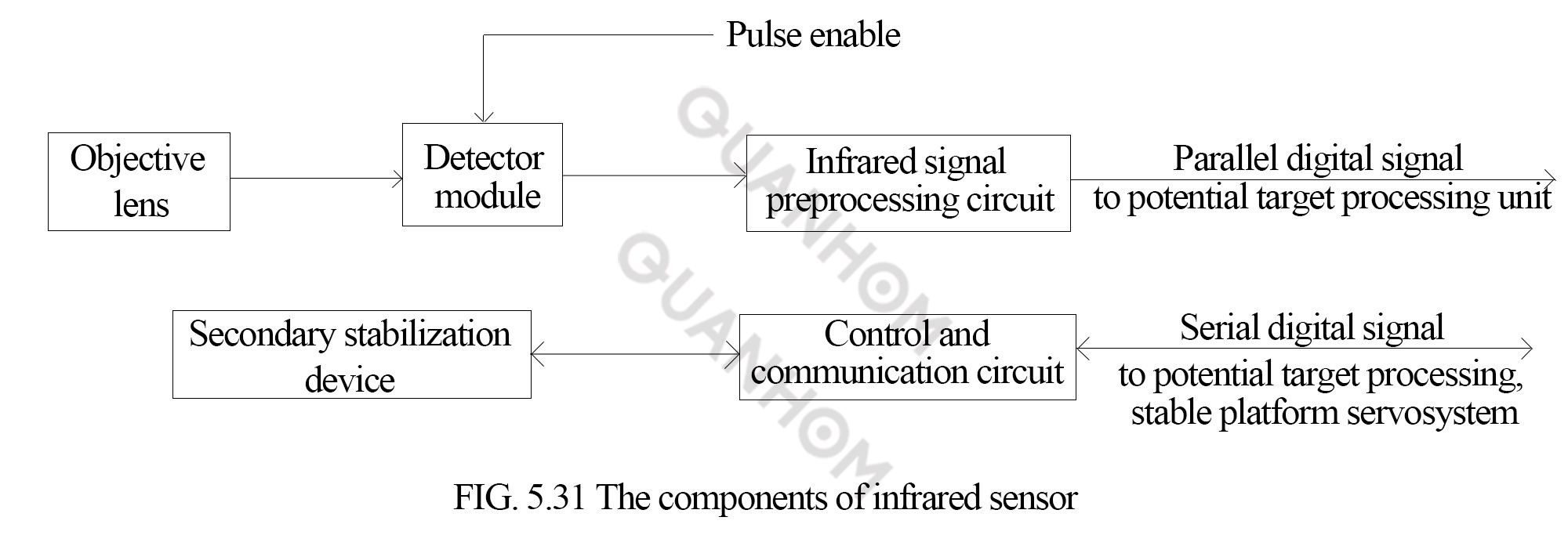

3. Infrared signal preprocessing circuit

(1) CDS:it is applied to the output signal of the detector to filter out the switching noise generated by the readout circuit of the detector.

(2) Electronic filtering: it can filter the low frequency noise, suppress the

high frequency noise and improve the signal-to-noise ratio.

(3) A/D conversion: it can be used to convert infrared signals into analog/digital quantities, and the quantization level is 12bit.

(4) NUC: it can correct the output signal of each of the 288 channels of the

detector. To ensure that under the action of the same infrared radiation

energy, the non-uniformity of the signals generated by each channel is less

than 0.5%. For detectors with linear response, it is sufficient to perform

two-point correction of responsivity and bias point; for detectors with

nonlinear response, a multi-point piecewise linear approximation algorithm is

required for correction. Since a certain type of infrared system needs to cover

360°, it is not possible to incorporate a temperature reference into the

system. Through research on two-point and multi-point piecewise linear

approximation and scene-based non-uniformity compensation, the work condition

is benign, then general hardware that can perform these three algorithms is

developed.

(5) Defect

elimination: it is replaced by the signal average of two non-defect channels in

the defect neighborhood to achieve defect elimination.

(6) Fusion and

sort: the signal in the previous column is delayed, which is equivalent to the

time between two adjacent columns. After the composite processing of the two

columns, a column of signals is formed to complete fusion and sort.

(7) Parallel interface: it is to output the digital infrared signal, the pixel

synchronization signal and the column synchronization signal to the potential

target processing unit in parallel, and simultaneously receive the column

synchronization signal from the goniometer unit.

4. Control and communication circuits

Functions:

(1) Receive a control signal (including a uniformity correction control signal,

a self-check control signal, and a gain control signal) from the potential

target processing unit, and send a self-check result signal to the potential target

processing unit.

(2) Receive the

platform attitude signal from the stabilized platform servo system.

(3) Control the

secondary stabilization device.

(4) Control the

infrared signal preprocessing circuit.

5. Secondary stabilizing device

The secondary

stabilization device consists of a mirror, a gyro, a servo motor and a drive

circuit. Its function is to perform secondary precise stabilization of the

infrared optical axis.