What Are the Characteristics of Infrared Thermal Imaging Lenses in Optical Design?

The infrared optical lens needs to be designed according to the detector's pixel and size, specific application occasions, and cost-effective factors. The followings are the specific characteristics of infrared thermal imaging lenses in optical design.

1. Large relative aperture

The diameter of the Avery disk of an ideal optical system is equal to 2.44λF. The wavelength of the mid-wave infrared in the two atmospheric windows is 3~5μm, and the wavelength of the long-wave infrared is 8~12μm, while the pixel size of typical infrared focal plane detectors is generally 15~30μm. If the F-number is too large, the diameter of the Airy disk will be much larger than the pixel size. Therefore, the F-number of an infrared thermal imaging lens is generally 1~2, which is a large relative aperture system.

When the F-number is 2, the diameter of the Avery disk with a wavelength of 5 μm is equal to 24.4 μm, and when the F-number is 1, the diameter of the Avery disk with a wavelength of 10 μm is also equal to 24.4 μm, which is already very close to the pixel size. Therefore, in order to achieve the spatial resolution that the detector can achieve, the dispersion of the optical system is required to reach or approach the diffraction limit, so the optical design will be more difficult.

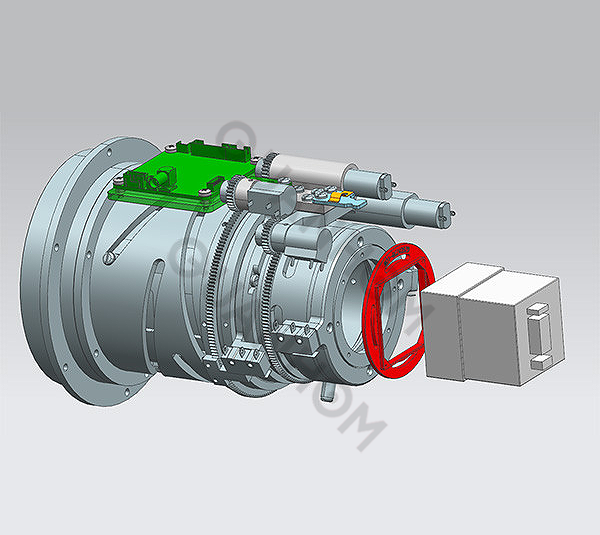

2. Cold shield or cold stop

In the cooled infrared focal plane detector, in order to avoid the influence of stray light and thermal radiation inside the lens barrel on the infrared focal plane detector and improve its detection performance, a cold shield or cold stop is designed in the Dewar of the infrared focal plane detector ( cold shield or cold stop). Only the infrared radiation entering the cold shield or cold stop can reach the infrared focal plane detector. In this way, the influence of stray light on the infrared focal plane detector can be effectively avoided.

The optical system used in this type of infrared focal plane detector with a cold shield or cold stop must use the cold shield or cold stop as its aperture diaphragm if it wants to make full use of the benefits of the cold shield or cold stop.

Otherwise, the aperture diaphragm of the infrared optical system will be located behind the entire optical system, or even far away from the optical system, destroying the symmetry of the optical system. In this way, the symmetry of the optical system cannot be used to eliminate the vertical aberration, which increases the difficulty of optical design.

Moreover, in this case, it cannot be made as an iris diaphragm like a visible light lens. At the same time, it cannot be made into a general-purpose lens, and a lens that matches the focal plane detector must be designed according to the size of the cold shield or cold stop and its distance from the focal plane.

3. Narcissuseffect

The infrared detector is colder than the surrounding environment, and its radiation may be reflected by some surfaces in the optical system and then fall on the detector, thus forming a cold image of the detector itself, with a black spot in the center of the image surface.

The simplest example is if there is a flat window placed perpendicular to the optical axis in front of the infrared optical system, ghost images of cold reflection will appear on the image surface. Therefore, cold reflections should be avoided as much as possible in the design of infrared lenses.

The infrared thermal imaging lens manufactured by Quanhom uses the latest optical design methods, special optical glass materials and special coatings, and other advanced technologies, and has excellent applications in many fields. If you want to know more about infrared optical systems after reading the above, you can get professional solutions by contacting us.

With excellent R&D technology and a strict quality inspection system, we have quickly become one of the leading manufacturers of Opto-electromechanical components. We are committed to producing various high-quality thermal infrared lenses (LWIR, MWIR, and SWIR) according to the diverse needs of customers. Our thoughtful one-stop service has also won the unanimous praise and trust of many customers. If you want to buy our infrared thermal imaging lenses, please contact us immediately!