Quanhom Technology Co., LTD is a company engaged in the area of development and production of thermal infrared optics. The high precision product range includes infrared lenses assemblies of SWIR/MWIR/LWIR , eyepieces, infrared lens elements, etc.

Home / All / Production and Quality /

What are the advantages and disadvantages of 2D drawings and 3D models?

Functions

What are the advantages and disadvantages of 2D drawings and 3D models?

1. What are the advantages and disadvantages of 2D drawings and 3D models?

2D Drawings:

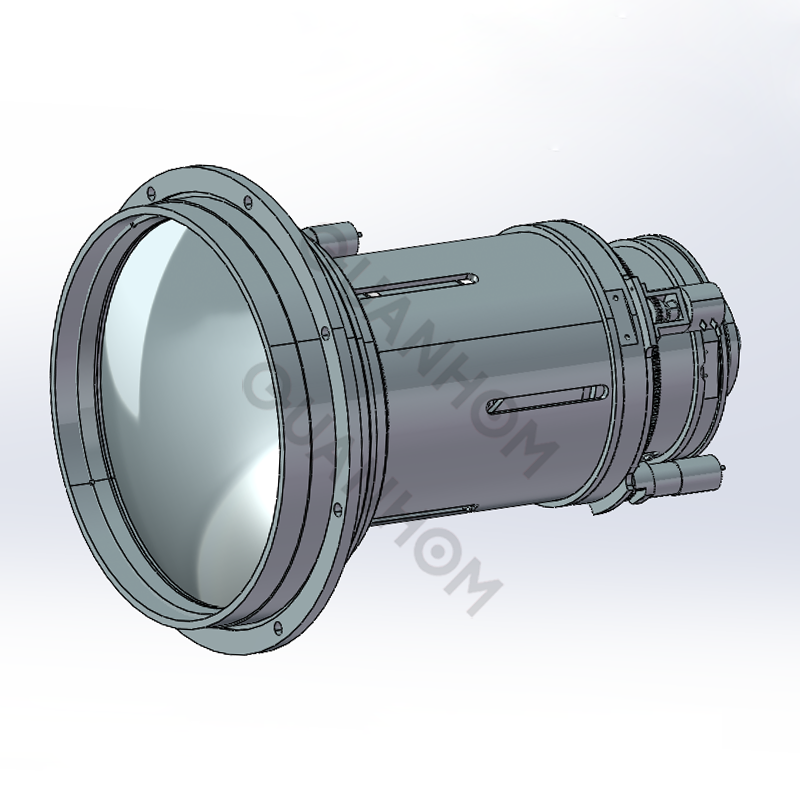

Advantages: It can completely express parts of all necessary information for manufacturing and processing, including dimensions, technical specifications, tolerance. The drawings can be converted into various formats, and printed (or output) drawings can be moved, shared and read in various environments.

Disadvantages: The drawing is complex and people requires certain professional knowledge to fully understand the information presented.

3D Models:

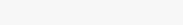

Advantages: The model is intuitive and clear, with well-defined relationships between parts. Even non-professionals can have a general understanding of the designed product through the 3D model. In addition, 3D models are easy to design and modify, which can greatly save design time and improve work efficiency. Moreover, 3D models are also convenient for sharing resource information.

Disadvantages: Specific software is needed to view detailed information. 3D models cannot intuitively express dimension data, surface roughness, and technical specification.

In short, customers can use 2D drawings to understand the product's approximate dimensional information, structure, shape, and so on. If you want to have a deeper understanding of the product, you can use 3D models, which can provide a more intuitive and three-dimensional display of the product, and offer a more comprehensive design understanding and evaluation.

(Take the GCZ92513KD as an example)

3D Model

2D Drawing

2. Does the dimensional deviation of the parts need to be consistent?

No need to keep consistent.

Dimensional deviation refers to the extent to which the dimension and shape of a part deviate from the design requirements due to various factors during the machining process. Each dimension of a part can have different dimensional deviations. Designers need to set appropriate dimensional deviations based on specific design requirements and actual manufacturing processes.

3. What are the factors that affect part dimensional deviation?

Factors affecting the dimensional deviation of parts include human factors, equipment, process and materials. Analyzing the main factors affecting parts machining errors is crucial for improving machining quality and reducing errors.

Quanhom Technology Co., LTD is a company engaged in the area of development and production of thermal infrared optics. The high precision product range includes infrared lenses assemblies of SWIR/MWIR/LWIR , eyepieces, infrared lens elements, etc.