Quanhom Technology Co., LTD is a company engaged in the area of development and production of thermal infrared optics. The high precision product range includes infrared lenses assemblies of SWIR/MWIR/LWIR , eyepieces, infrared lens elements, etc.

Functions

What is NETD?

Thermal sensitivity (NETD) stands for Noise Equivalent Temperature Difference, which is a critical parameter for evaluating Medium-Wave Infrared (MWIR) and Long-Wave Infrared (LWIR) thermal imaging cameras. It is a value that represents the signal-to-noise ratio of the temperature difference, which is equivalent to the instantaneous noise of the imaging camera. Therefore, it approximately represents the minimum temperature difference that the thermal imaging camera can resolve, which is directly related to the clarity of its measurement.

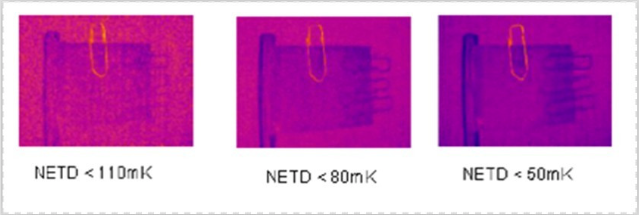

When selecting sensors with the same pixel configuration and under a fixed thermometric scale, using instruments with different thermal sensitivities to take pictures, the results are as follows:

Under different thermal sensitivities, the pictures presented are very different. The smaller the value of sensitivity, the better the thermal sensitivity and the clearer the picture.

Measurement of NETD

(1) Two-point Method

The two-point method is a common way to measure the NETD of an infrared imaging camera. It is based on two assumptions: 1. The surface of the target is uniform without local heat sources. 2. The noise between the pixels of the imaging camera is independent.

The specific steps are as follows:

1. In a completely dark environment, select two pixel points with moderate spacing as the target point.

2. Measure the output signal of the thermal imaging camera and calculate the signal difference between the two pixels.

3. Calculate the corresponding NETD according to the temperature characteristics of the thermal imaging camera.

(2) Averaging Method

The averaging method is a simple and commonly used method for measuring the NETD of thermal imaging cameras. It is based on the statistical properties of the imaging camera output signal for higher measurement accuracy.

The specific steps are as follows:

1. Select an appropriately sized pixel area under stable environmental conditions.

2. Measure the average and standard deviation of the output signals of all pixels in the area.

3. Calculate the NETD based on the temperature characteristics and standard deviation of the thermal imaging camera.

(3) Spectrum Analysis Method

Spectral analysis is a method of measuring the NETD of an infrared imaging camera based on the signal spectrum, which is suitable for thermal imaging cameras with obvious noise frequency characteristics.

The specific steps are as follows:

1. The signal output by the imaging camera is subjected to Fourier transform to obtain the spectrum of the signal.

2. Analyze the noise components in the spectrum and calculate the NETD.

Factors affecting NETD:

(1) Corrected Temperature Measurement Range. Depending on the selected temperature measurement range and object temperature, the noise readings will be different. However, as long as there is significant thermal contrast in the image and the temperature of the target area is much higher than the background temperature, it will not affect the measurement accuracy too much.

(2) Detector temperature. If the imaging camera is placed at a higher temperature, the system noise will increase, the extent of which depends on the internal stability of the infrared thermal imaging camera.

(3) The F-number of the camera lens. A lower F-number means a larger aperture, which allows more infrared radiation to enter the camera. Generally, a larger aperture (lower F-number) receives more infrared radiation, which helps to improve the signal-to-noise ratio of the imaging. In theory, the lower the F-number, the lower the noise values and the better the image quality.

Quanhom Technology Co., LTD is a company engaged in the area of development and production of thermal infrared optics. The high precision product range includes infrared lenses assemblies of SWIR/MWIR/LWIR , eyepieces, infrared lens elements, etc.