What are the contact forms when using the pressing ring and spacer to fix the lens?

What are the contact forms when using the pressing ring and spacer to fix the lens?

According to the summary of scholars and research institutions at home and abroad, there are five main contact forms among the pressing ring, the spacer and the concave-convex lens: sharp corner, tangential, toroidal, spherical, and oblique plane.

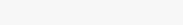

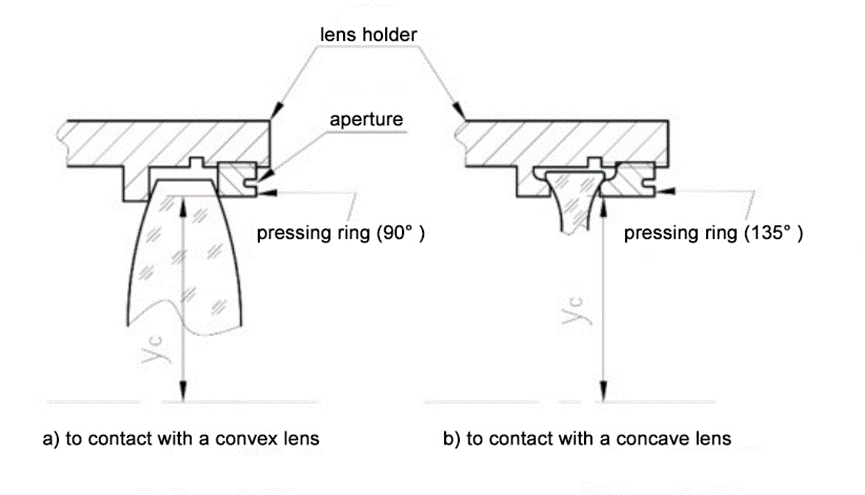

1) Sharp corner interface

On a pressing ring or spacer, a curved surface with a radius of about 0.05mm is ground at the intersection of the end face and the cylindrical surface. The ground surface is called the sharp corner interface, and its contact form is as follows:

2) Tangential interface

The interface formed by the contact between the surface of the convex lens and the surface of the pressing ring or the spacer is a tangential interface. Different from the sharp corners, the tangential interface is not used to fix the concave spherical lens, but the convex spherical lens.

3) Toroidal interface

The following figure shows the contact form of the toroidal interface.

4) Spherical interface

The spherical interface contact form is that the metal pressing ring or spacer is in seamless contact with the spherical surface of the lens. Because the axial load is evenly distributed on the spherical contact surface, there is no pressure concentration in principle. However, the assembly precision of this contact form is particularly high, and the lens and the metal pressing ring must be machined with high precision, so it is difficult for average companies to accept it due to the high cost.

5) Oblique plane interface

As shown in the figure below, the oblique plane interface is the same as the spherical interface with a comparatively big contact area, so that the contact pressure generated by thrust load is distributed evenly. But its contact surface is not real plane. The metal pressing ring or spacer surface is also not parallel to the lens surface. This kind of contact form will inevitably lead to point contact and line contact, which will cause a little bit high local pressure.