How are infrared optical lenses designed and produced?

1. Determine the use band according to the usage scenario, system requirements, cost requirements, etc. Most of the occasions use a single band such as short wave, medium wave or long wave, but some special occasions need to use multiple bands.

2. After the band is determined, according to the overall performance requirements of the infrared system, the optical path layout is carried out, the technical parameters such as the focal length and the field of view of the infrared lens are determined, and the imaging quality requirements of the lens are determined at the same time.

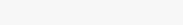

3. Select the initial structure form of the lens according to the performance index and optical path layout of the infrared optical lens. The initial structure is a typical structure form summed up in the case of a lot of design experience. The following is a brief list of a few:

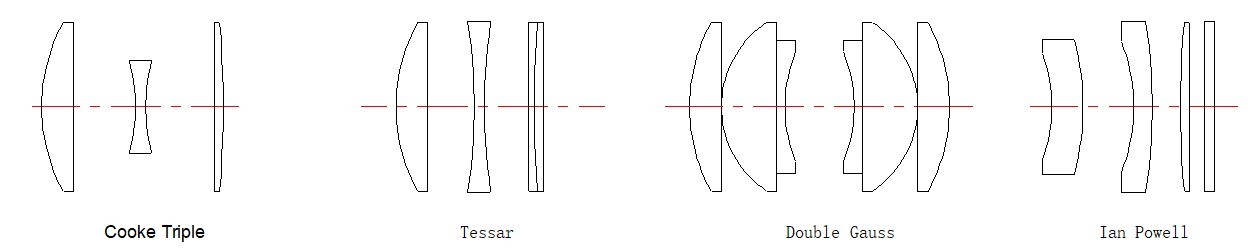

4. Perform aberration correction and other optimizations on optical lenses through optical design software or other auxiliary tools.

5. Image quality evaluation of corrected and optimized optical solutions.

6. Calculate, assign and formulate processing tolerances and assembly tolerances of infrared optics components and assemblies.

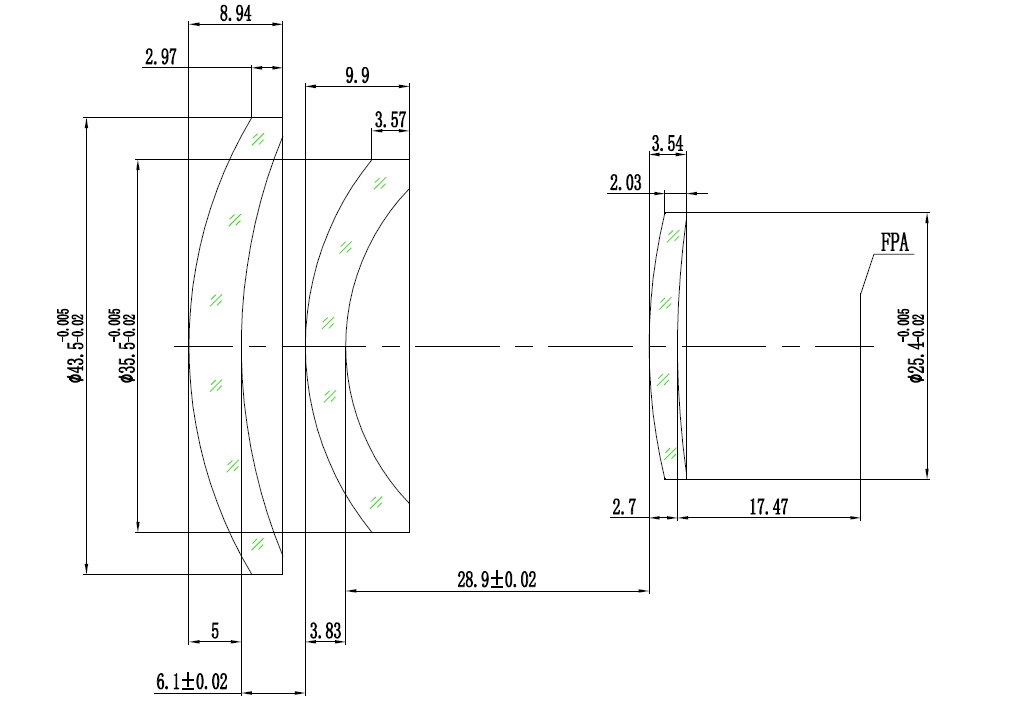

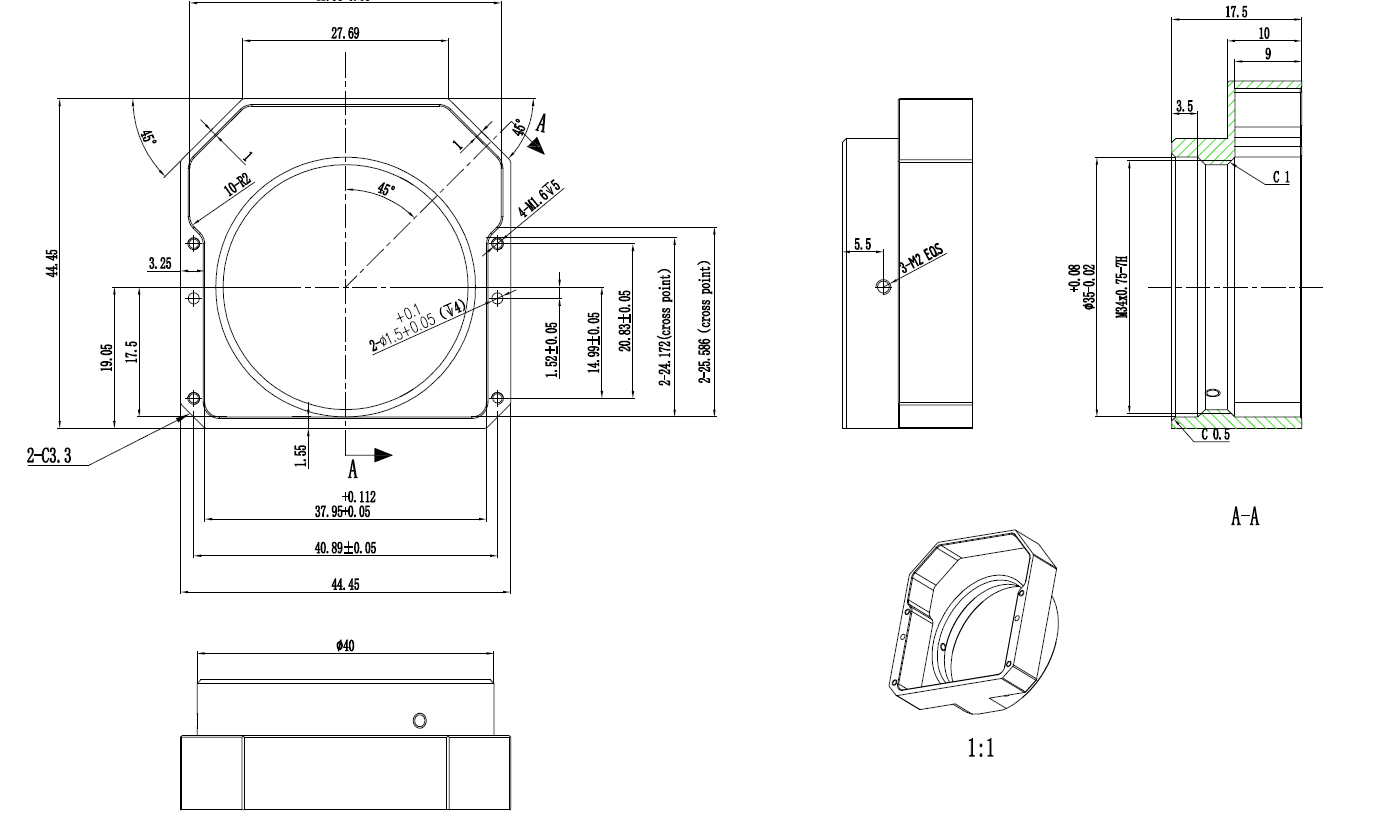

7. Draw infrared optical system diagrams, components and parts diagrams, etc.

8. All drawings are transferred to trial production drawings and start production trial production.

9. Test/debug the trial samples, issue test reports, optimize defects,

10. Officially put into mass production and use.